PU/PVC Synthetic Leather Manufacturing Machine

The Principle & use: Release paper after PU, PVC oil or water-based resin with the liquid applied to the surface, low material after the dry cooling process, then coated with the adhesive layer, using BASE / fabric to send fit device substrate and low material compound, after drying, cooling, stripping device will be finished synthetic leather with the release paper stripped coiling; by embossing, soft lines, intaglio surface of different post-processing technology, can produce a comparable appearance in the dermis and soft to the touch comfortable, stylish varying the synthetic leather; widely used in shoes, clothing, bags, automotive interiors, home improvement and sports equipment production use.

Product introduction:

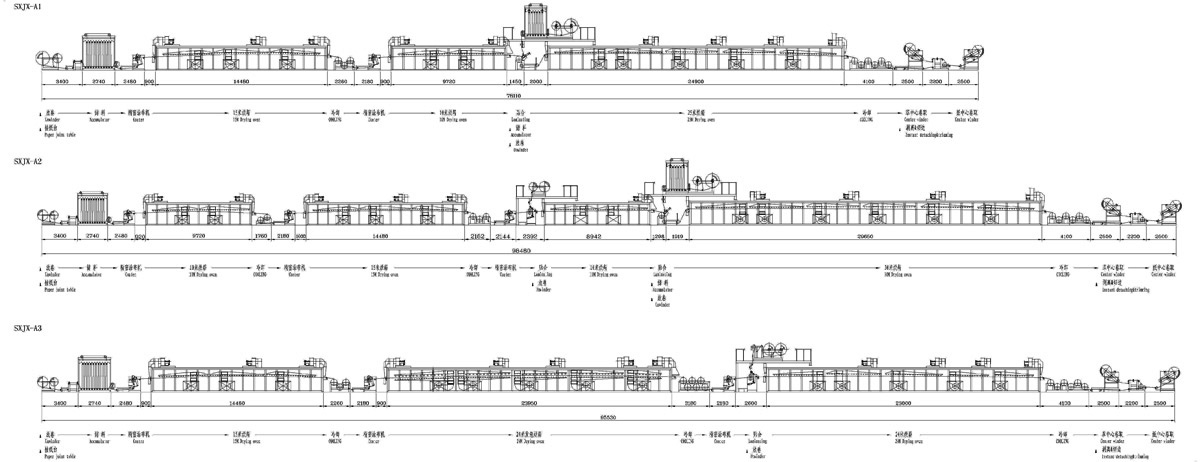

One, the basic specification, and mechanical

The release paper unwinding + paper receiving station

Release paper storage material device

1st precision coating machine

Drying box + cooling

II Precision coater

Drying box plus fitting device

Fabric sent

Drying box + cooling

Stripping trimming device

Synthetic leather take-up

Release paper take-up

Temperature: 70 ℃ -180 ℃

Main power: inverter motor drive system and pneumatic tension linked to the control system

Mechanical speed :5-40M / min

The Principle & use

Release paper after PU, PVC oil or water-based resin with the liquid applied to the surface, low material after the dry cooling process, then coated with the adhesive layer, using BASE / fabric to send fit device substrate and low material compound, after drying, cooling, stripping device will be finished synthetic leather with the release paper stripped coiling; by embossing, soft lines, intaglio surface of different post-processing technology, can produce a comparable appearance in the dermis and soft to the touch comfortable, stylish varying the synthetic leather; widely used in shoes, clothing, bags, automotive interiors, home improvement and sports equipment production use.

Types of fabric: knitted, woven, cotton, chemical fiber, BASE and other fabrics

Heating mode of heat sources: steam or hot kerosene

The release paper unwinding + paper receiving station

Release paper storage material device

1st precision coating machine

Drying box + cooling

II Precision coater

Drying box plus fitting device

Fabric sent

Drying box + cooling

Stripping trimming device

Synthetic leather take-up

Release paper take-up

Temperature: 70 ℃ -180 ℃

Main power: inverter motor drive system and pneumatic tension linked to the control system

Mechanical speed :5-40M / min

The Principle & use

Release paper after PU, PVC oil or water-based resin with the liquid applied to the surface, low material after the dry cooling process, then coated with the adhesive layer, using BASE / fabric to send fit device substrate and low material compound, after drying, cooling, stripping device will be finished synthetic leather with the release paper stripped coiling; by embossing, soft lines, intaglio surface of different post-processing technology, can produce a comparable appearance in the dermis and soft to the touch comfortable, stylish varying the synthetic leather; widely used in shoes, clothing, bags, automotive interiors, home improvement and sports equipment production use.

Types of fabric: knitted, woven, cotton, chemical fiber, BASE and other fabrics

Heating mode of heat sources: steam or hot kerosene

technical parameter:

Second, type: COM knife fine coated

Purpose: the surface of release paper, PU glue, PVC plastic

Features: high-precision coating roller and precision comma knife processing to ensure that the fine-tuning of the high-precision gap, the gap control accuracy (± 0.03), the coating weight is stable and uniform;

The man-machine interface touch screen controls, convenient, intuitive operation;

Advance and retreat of the knife and jump the Yiu use low-friction cylinder, electric control action is more sensitive and accurate;

The motor adopts frequency control system, the adjustment range PLC control.

Third, the drying oven

Features:

Independent drying system design nozzle air flow and temperature uniformity;

Oven on both sides of special specially designed magnetic door switch, easy to clean, repair;

Streamlined design of the appearance;

PID automatic temperature control system and a new and efficient closure of the entire oven;

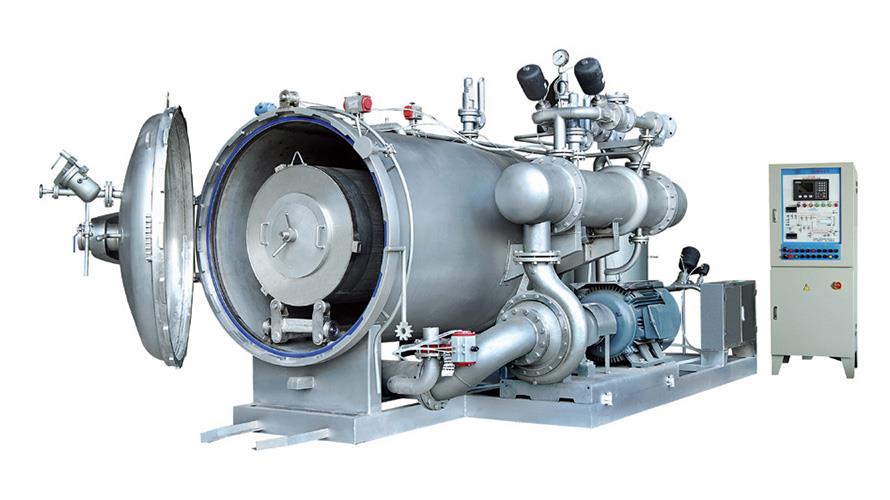

Fourth, the water cycle cooling

Features: cooling roller S-type arrangement, the cooling effect is good;

Fifth, the fitting device

Sixth, the synthetic leather / release paper take-up

7, electrical cabinets

Purpose: the surface of release paper, PU glue, PVC plastic

Features: high-precision coating roller and precision comma knife processing to ensure that the fine-tuning of the high-precision gap, the gap control accuracy (± 0.03), the coating weight is stable and uniform;

The man-machine interface touch screen controls, convenient, intuitive operation;

Advance and retreat of the knife and jump the Yiu use low-friction cylinder, electric control action is more sensitive and accurate;

The motor adopts frequency control system, the adjustment range PLC control.

Third, the drying oven

Features:

Independent drying system design nozzle air flow and temperature uniformity;

Oven on both sides of special specially designed magnetic door switch, easy to clean, repair;

Streamlined design of the appearance;

PID automatic temperature control system and a new and efficient closure of the entire oven;

Fourth, the water cycle cooling

Features: cooling roller S-type arrangement, the cooling effect is good;

Fifth, the fitting device

Sixth, the synthetic leather / release paper take-up

7, electrical cabinets

Sample display:

Composition figure

Video:

Recommended products

more+

Hot news

more+

The use and classification of rubber machine

2022-06-30

86-595-85730606

86-595-85730606

閩公網安備35058202001412

閩公網安備35058202001412

86-595-85730606

86-595-85730606